ThermalTight™: Water – Air – Vapor + Thermal in One Panel

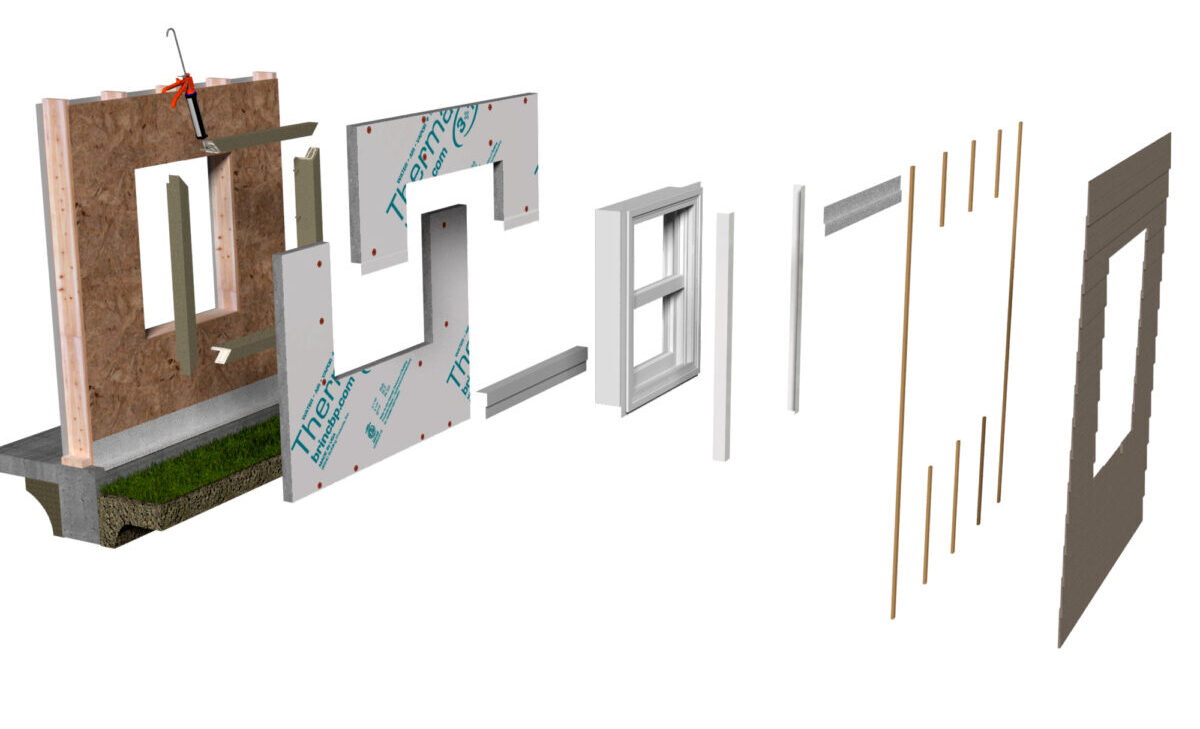

Building science experts have proven that there need to be four control layers in any wall: Water, Air, Vapor, and Thermal. Not only do the layers matter, but their placement in the wall assembly makes a big difference in how well they function.

ThermalTight™ moves the WRB to the exterior of the insulation, so it manages bulk water at the outer surface of the wall assembly. This provides superior protection compared to moisture damage on walls where WRB is installed on the sheathing. Air movement is also stopped at the outer surface of the wall when ThermalTight™ is sealed, completing the air control layer, and making ThermalTight™ an effective air barrier.

The ThermalTight™ System makes it easier to build better, with a wall system that solves the challenge of building airtight and continuously insulated – with one less trip around the building. The ThermalTight™ System is backed by a 15 year warranty.

ThermalTight™ Panels are available in 3 different thicknesses: 1-1/16″ R-5, 1-1/2″ R-7, 2-1/8″ R-10, and 3 different size panels: 4′ x 8′, 4′ x 9′, and 4′ x 10′.

The WRB: Water, Air & Vapor

The WRB: Water, Air & Vapor

The self-gasketing, non-woven, non-perforated polypropylene WRB is laminated to the Neopor GPS rigid insulation, resulting in one panel that insulates and protects the building envelope.

Each ThermalTight™ panel features a multi-layered WRB material that not only controls water and air, but it’s also vapor permeable (VP) – allowing moisture to move in both directions. While not as important as bulk water management, the high-performance homes we build today are tighter than they’ve even been before, making moisture management an important consideration.

ThermalTight™ features an innovative patented flap system that overlaps the rigid foam boards 2″ on all 4 sides. These flaps are used to seal the panels together, allowing the WRB to function not only as a water barrier, but as a continuous air barrier too.

The SEAMS: BRINC Fluid FS

The SEAMS: BRINC Fluid FS

Sealing seams underneath the flaps, rather than on top of each seam, prevents the “reverse shingle” effect common with taping most panel systems. This results in a continuous air & water barrier with excellent drainage.

Where two ThermalTight™ panels meet, one panel flap is removed, leaving just one flap to seam the panels together. BRINC Fluid FS is applied as a continous bead under the flap, 1″ from the join on the adjoining panel. Then the flap is smoothed over with firm, diagonal pressure.

BRINC Fluid FS is a dual-purpose flashing and sealant designed for use with ThermalBuck™ and ThermalTight™. It is compatible with a variety of substrates, including window flanges and casings, wood framing, OSB sheathing, plywood sheathing, steel framing, concrete, and masonry.

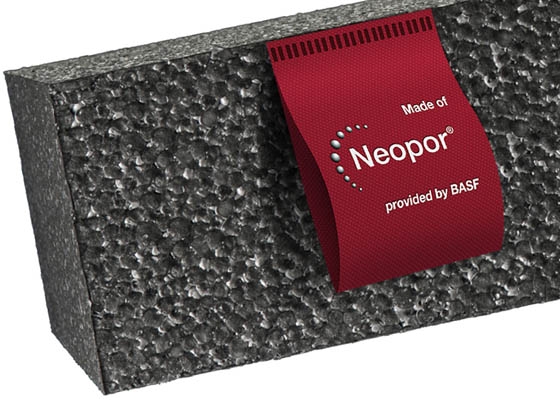

The INSULATION: Neopor® GPS Insulation

The INSULATION: Neopor® GPS Insulation

Neopor® GPS maintains the highest long-term R-value of any insulation material on the market.

Unlike some rigid foam insulation materials, Neopor® Graphite Polystyrene increases in R-value as temperatures drop. Made up of small pockets of air rather than harmful blowing agents, the graphite in Neopor® GPS reflects radiant heat energy – increasing the material’s resistance to the flow of heat. Rated at an R-value of 4.7 per inch. at 75°, the R-value for Neopor® GPS increases to R5 per inch at 40° and R5.2 per inch at 25°.

Sustainability

Neopor® Plus GPS is GREENGUARD Gold Certified for products for low chemical emissions, and been referenced by both the Collaborative for High Performance Schools (CHPS) and the Leadership in Energy and Environmental Design (LEED®) Building Rating System.

Neopor® contains no harmful blowing agents (GHGs), relying instead on graphite, making it one of the greenest types of rigid exterior insulation materials. The manufacturing process of Neopor® rigid foam uses up to 30% less material than other rigid insulation types, reducing the consumption of natural resources.

BASF is proud to be a part of team behind the EC3 tool, designed to help building professionals quantify, report and reduce the embodied carbon impact of their projects. Embodied carbon is the carbon dioxide emitted during the manufacturing, transportation and installation of building materials. (neopor.basf.com)

Learn more about building with the benefits of Neopor® GPS at neopor.basf.us.

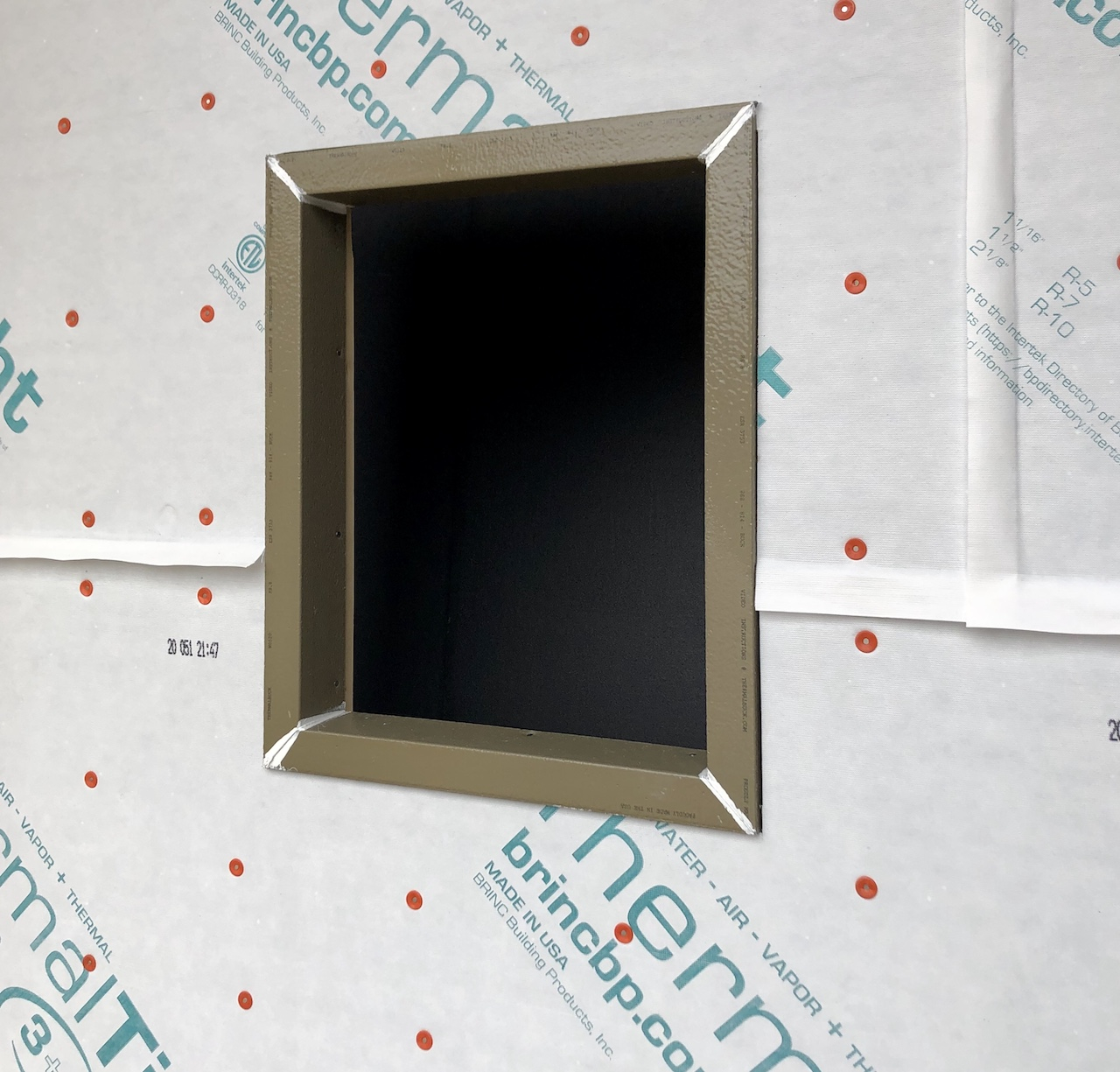

ThermalBuck™: The high-performance window buck

ThermalBuck™: The high-performance window buck

Described as a “game-changer” in the building material industry, ThermalBuck™ works will all types of exterior insulation materials.

Designed to solve the challenges of installing windows with exterior insulation, ThermalBuck™ extends the mounting point for windows & doors to create a flush plane for cladding attachment.

Visit www.ThermalBuck.com to learn how to properly seal your windows and doors.